Electric motors have been around for a very long time. They were originally invented in the 19th century, but it wasn’t until 1893 that Thomas Edison and Elihu Thomson developed the first commercially available AC induction motor. These early models had quite a few drawbacks, which is why today’s modern electrical motors are so much better than those old ones.

Today, there are many different kinds of electric motors on the market, with different speeds and power ratings. There are also different sizes of motors, ranging from the size of a match head to the size of an automobile engine. The type of motor you choose depends on the application that you need to use it for. For example, you would not want to use an industrial grade motor in a household appliance.

The Basics of Electric Motors

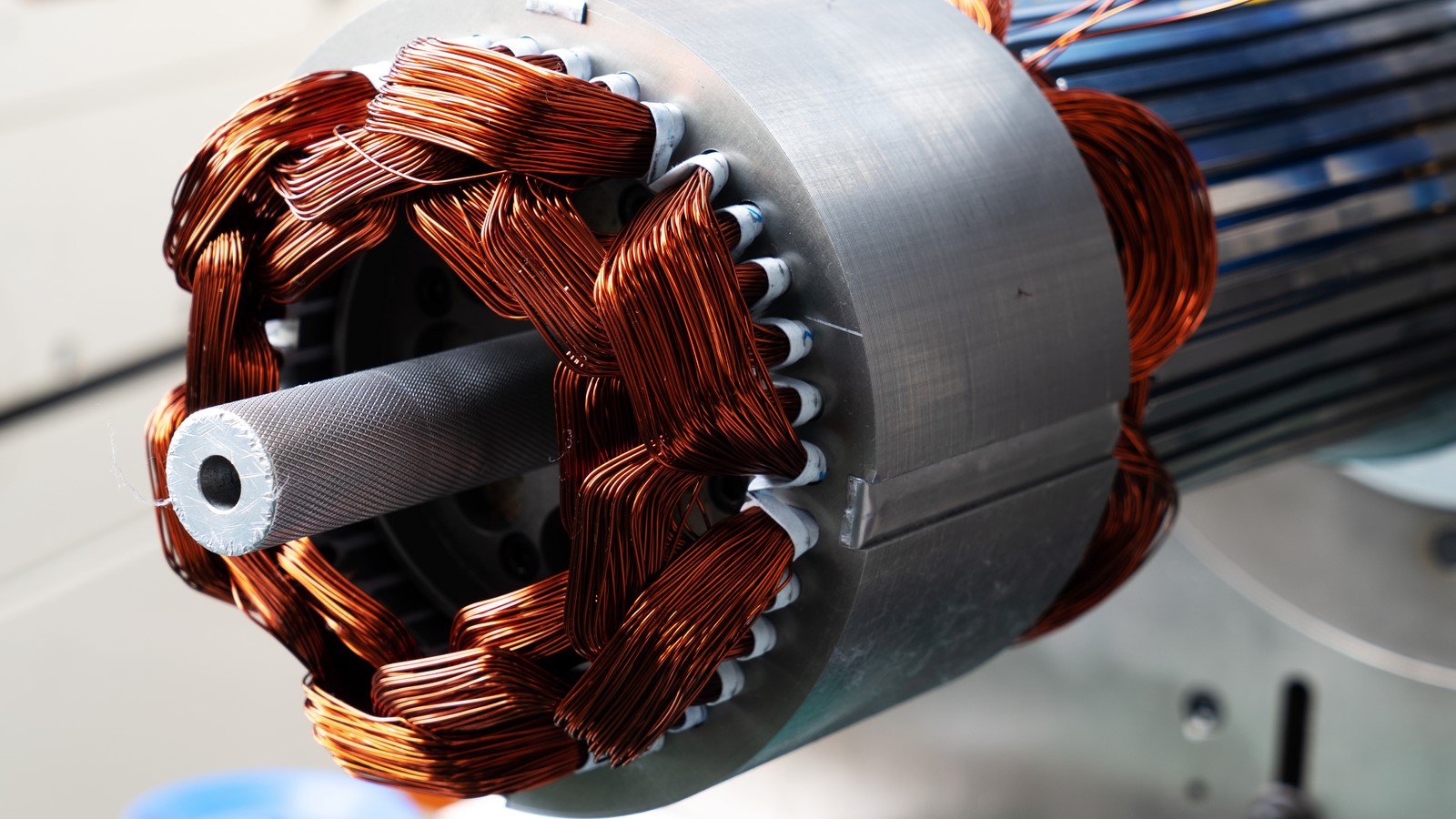

An electric motor is a device that converts electrical energy into mechanical motion. There are many different kinds of electric motors, but the most basic one consists of a rotor (a rotating part) connected to a shaft. As the electricity flows through the stator, it creates an electromagnetic field around the stator. This magnetic force causes the rotor to rotate.

In order to make sure that the rotation continues, the stator must be attached to the frame. If you want to learn more about how electric motors work, then you should read the article below.

There are two main types of electric motors: induction motors and permanent magnet motors. Induction motors use a changing current in the coils of the stator to create a magnetic field.

Permanent magnets are made up of tiny pieces of metal that have been arranged to form the shape of the motor. When the magnets pass by the poles of the stator, they cause the rotor to spin.

Both of these types of motors can produce high torque. But, the type of motor you choose depends on what you need. For example, a low-speed induction motor is usually used for small applications, such as fans.

How Does a Motor Lose Efficiency?

A car engine is a very complicated machine. If you want to understand how it works, you have to know its parts. The first thing that you need to consider when looking at the internal workings of an automobile is the crankshaft. This is the part that connects the pistons of the cylinders together. When you look inside the engine, you’ll notice the flywheel.

This piece spins around at a high speed, and it helps to provide energy for starting the vehicle. After the starter starts up, the power from the flywheel is transferred to the crankshaft.

If you look closely at this, you will notice that the crankshaft is connected to two main shafts. One of these is the camshaft, and the other one is the timing belt. Both of them help in the movement of the valves, which are located near the top of each cylinder.

When you start a car, the spark plug fires up, and the mixture of air and fuel explodes. As the explosion occurs, it pushes down on the piston, causing the crankshaft to rotate. At this point, the camshaft begins to turn, which causes the valve to open. Once the valve opens, the pressure in the combustion chamber drops, and the gas expands.

How Long Do Electrical Motors Last?

Electrical motors are used for a wide variety of tasks. For example, they might be found in appliances like washing machines, dishwashers, refrigerators, etc.

When you use an electric motor to power your home appliance, how long does the motor last before it needs replacing? This depends on several factors, including the type of motor that you have, the amount of electricity that you consume, and the frequency with which you use your appliance.

For instance, you should replace a single-speed washer when it reaches the end of its life cycle. However, you can expect to keep using a three-phase induction motor for at least 10 years.

If you want to learn more about the lifespan of various types of electric motors, then you should read the article below.

Here are some tips that will help you to extend the life of your motor.

Avoid using the same load. If you regularly run your clothes dryer or refrigerator, then you need to change the way that you operate them. The best thing to do is to switch from a standard setting to one of the high energy settings. You’ll also find that this helps to reduce wear and tear on the machine.

Use low voltage motors. Most people don’t realize that motors are rated by their ampere hours.

What Affects the Efficiency of an Electric Motor?

A lot of people don’t know that electricity is used to power everything from computers, to cars, to appliances. The most important part of an electrical system is the electric motor. This article will discuss how motors work, and why they have different efficiencies.

When you look at a car engine, you’ll notice that there are two main parts: the cylinder and the piston. The piston moves back and forth inside the cylinder. As the piston moves, it pushes the fuel and air mixture into the combustion chamber. When the piston reaches the top of the cylinder, it compresses the gas, creating a large amount of pressure. At this point, the spark plug ignites the compressed gas, and the explosion begins.

An electric motor works in a similar way. However, instead of a piston, an electric motor has a rotor. A rotor is like a spinning wheel. It spins around, pushing the magnets on its surface. Because the magnet is pushed by the rotor, the magnetic field changes, causing the coil to produce an alternating current.

The alternating current causes the armature to move. This movement creates torque, which turns a shaft. If the shaft rotates faster than the speed of the motor’s rotation, then the motor will be more efficient.

Do Electric Motors Get Weak Over Time?

If you’re thinking about buying a new appliance, such as an air conditioner or refrigerator, then you might be wondering whether or not these appliances will last you a long time. If so, then this article is perfect for you. This guide explains why electric motors tend to lose their strength over time.

When you use electricity, the current passes through wires. The wire itself doesn’t generate any heat, but it does have resistance. That means that the more current flows through the wire, the hotter the wire gets. Eventually, however, the wire becomes hot enough to burn the metal inside. When that happens, the motor stops working.

You can help to prevent this from happening by making sure that you change the fuse or circuit breaker on your power supply every few years.

If you need a replacement part, then you should make sure to buy one that’s made to last. For example, you shouldn’t purchase an old-fashioned model that has been around for many decades. Instead, you should opt for something with modern technology.

That way, the parts will work properly and they’ll also last longer.

Is There Any Way to Make Them Last Longer?

There is no doubt that electric motors have become extremely popular over the years. In fact, most of the cars on the road today use an electric motor. If you’re looking for the best type of electric motor, then this article will help you understand everything you need to know.

When you buy a new car, you’ll notice that all of the parts are connected to each other using wires. The wire harnesses are usually made up of multiple electrical connections. However, when you run these wires through the engine compartment, they may be exposed to heat and moisture. This can cause the wires to break down and lose their connection.

To avoid this, you should keep the wiring away from the hot areas of the vehicle. You should also take care to protect it by wrapping the wires in a rubber sleeve.

Another thing that you should consider is that the wires that connect the different components together can sometimes get tangled up. When this happens, the wires might not work properly. To prevent this, you should look for ways to organize your wiring system. For example, you could put a box on top of the dashboard where you store all of the wires.

If you want to learn more about how to make electric motors last longer, then you should read this article.

What Are the Pros and Cons of Using Permanent Magnets in Electric Motors?

Permanent magnet motors (PMM) are used in many different applications. PMMs have the ability to produce high torque at low speeds. This makes them ideal for use in vehicles.

However, the biggest problem with these motors is that they are expensive to make. As a result, most of the PMMs available on the market today are made from rare earth materials. Rare Earth Materials: The Pros and Cons of Using Permanent Magnets in Electric Motors

Rare earth elements are naturally occurring minerals. They are extremely important for making various electronic devices. However, they are also very difficult to mine and process. Because of this, the price of rare earths has skyrocketed.

This means that you will need to spend a lot of money on your motor if you want one that uses rare earths. In fact, it can cost more than $10,000 per kilogram of rare earth.

As a result, manufacturers who rely on PMMs are forced to charge their customers an arm and a leg.

If you’re looking for a cheaper option, then you might be interested in using a hybrid motor instead. Hybrid motors combine permanent magnets and electromagnetic coils. They offer similar performance to a pure PMM. However, they don’t require the same level of maintenance.

![Motors-e1594809255433[1]](https://autoprecaution.com/wp-content/uploads/2022/11/Motors-e15948092554331.jpg)